-

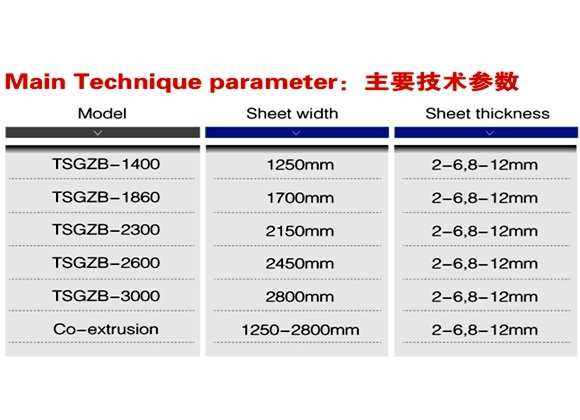

Extruder

Extruderour extruder has advantage of high capacity and strong plasticizing ability, it can make high quality PP hollow sheet with even 60% filler masterbatch.

-

Mould

Mouldwith advantages of high quality, easy operation, uniform material flow and stably production, our PP hollow sheet mold can make 2-6mm thickness in one die.

-

Vacuum calibrating system

Vacuum calibrating systemadopting self-created vacuum cooling system ,Tongsan PP hollow sheet line can achieve high speed production,operational safety and easy maintenance

-

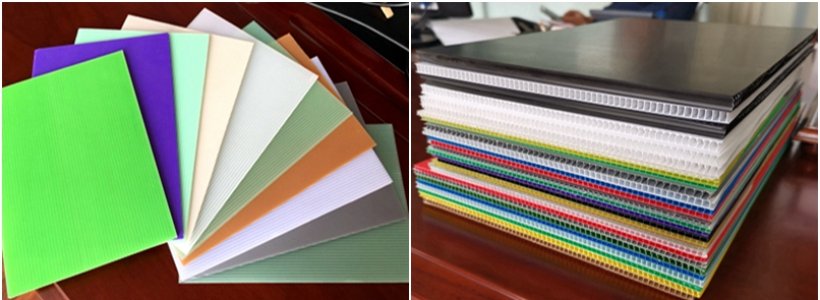

After cutting and printing

After cutting and printingmanually cutter and auto cutter are optional, auto cutter can equip wastage cleaning function.

-

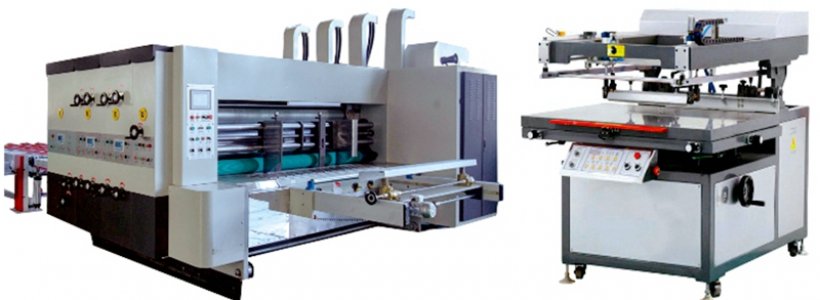

Multi-color printing surface

Multi-color printing surfacewe can provide both manually printer and high automatic printer, HD printing effect can also be achieved

-

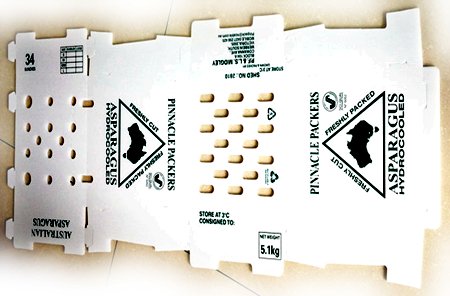

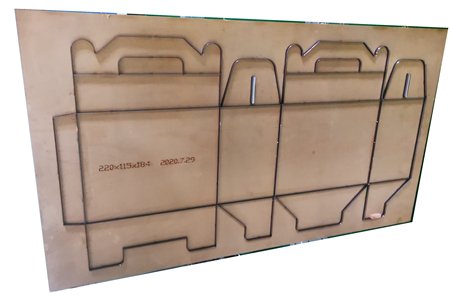

Cutting and printing template

Cutting and printing templatewith rich experience, we can also supply the cutting and printing template according to customer's requirements.

-

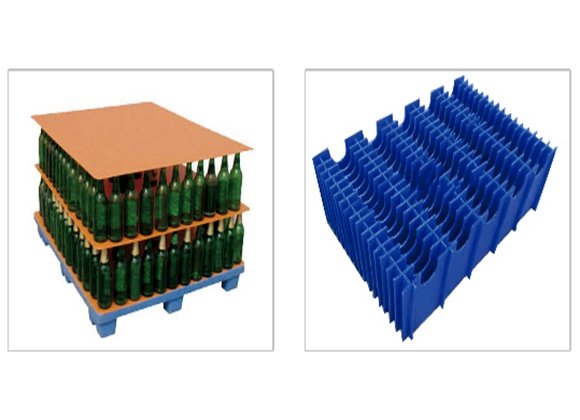

Turnover box

Turnover boxAdvantage: non-toxic, no smell, pollution-free, water-proof, anti-moisture, corrosion resistance, light weight, tough-resisting, thermal shock proof, economy and durability, rich colors etc

-

Packing box

Packing boxwidely used in advertisement, decoration, transportation and package for machinery, electron, home appliance, medicine, food, glass, agricultural products.

-

Advertisment

Advertismentreusable and 100% recyclable,non-pollution in production, PP hollow sheet is environment-friendly products,it is ideal packing material for replacing paper